SINGER® Heavy Duty 6800C Troubleshooting TipsUpdated 24 days ago

Whether you are an experienced sewist or just starting, these helpful tips will help keep your sewing machine running its best!

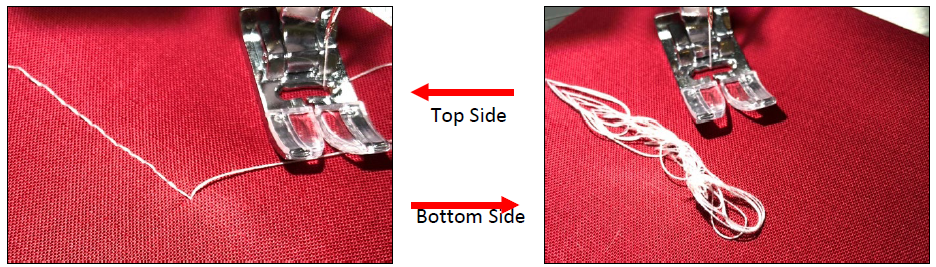

Thread Loops on Underside of the Fabric

If your stitches appear to look normal on the top side of the fabric, there are lots of thread loops or excess thread on the underside, although it seems counter-intuitive, thread that is looping on the underside of the fabric normally indicates that the upper thread is not correctly threaded. This can happen when the upper thread is not correctly placed in the tension mechanism during the threading process, and/or the thread has not been threaded through the eye of the take-up lever.

This can usually be resolved by first completely removing the upper thread from the machine, and then rethreading the machine. But, before you start rethreading, first raise the presser foot lifter, so that the thread can be properly seated in the tension mechanism. Then, turn the hand wheel toward you until you can see the take up lever, so you can make sure its eye gets threaded as well.

Bobbin Thread Showing on the Top Side of the Fabric

Bobbin thread can pull up to the top side of the fabric if the top thread tension is too tight, if the threading path is obstructed, or if the bobbin thread is not correctly placed in the bobbin case tension.

threading path is obstructed, or if the bobbin thread is not correctly placed in the bobbin case tension.

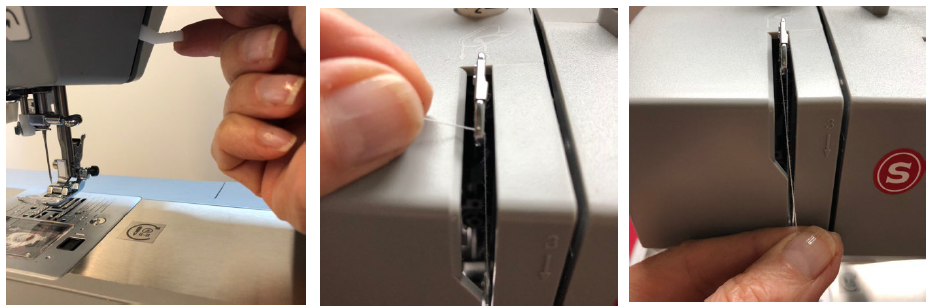

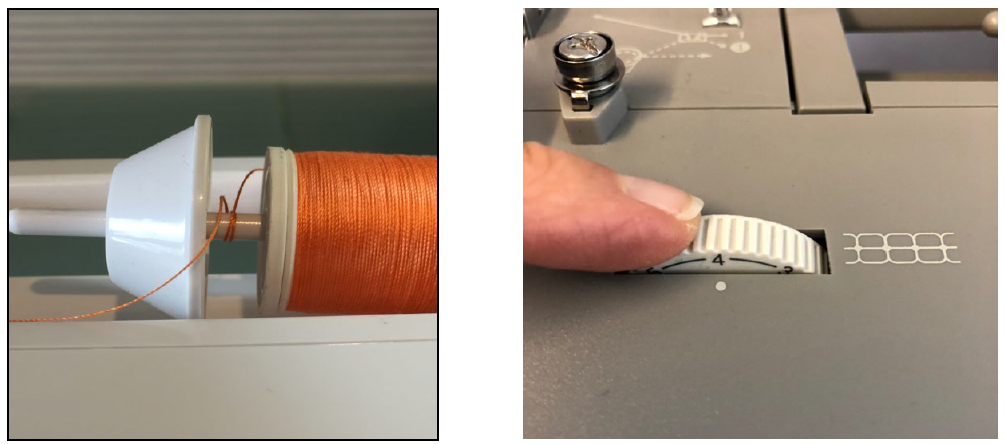

First check that the upper thread is feeding freely without obstruction. Thread can get obstructed if the spool cap at the top of the machine is not pushed up next to the spool (see photo). Thread can also get obstructed if it is getting caught on any rough spots on the spool itself.

Next, make sure the bobbin is correctly seated in the bobbin case (bobbin holder). Also, check that the upper thread tension is not set too tightly for the thread and fabric you are using. The setting range from 3 to 5 is normal for most regular sewing thread.

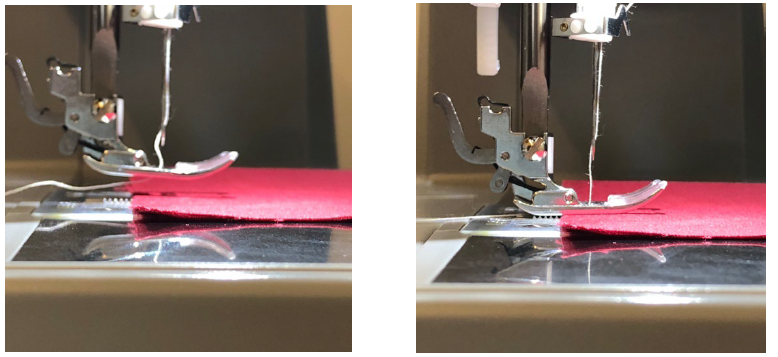

Fabric Is Not Feeding

If the machine is not feeding fabric when you start sewing, it could be that the presser foot lifter has not been lowered before stepping on the foot control. Lower the presser foot lifter so the foot is in contact with the fabric, then resume sewing.

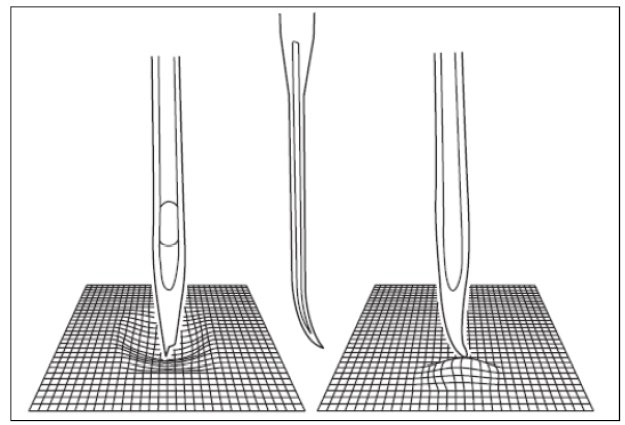

The machine may also not feed fabric if the stitch length setting has been set to “0”, or too short of a stitch length setting for the thickness of thread being used. Increase the stitch length setting and resume sewing.

Another reason the fabric may not be feeding is if the feed teeth are disengaged. Make sure the feed teeth are properly engaged for regular sewing.

(Note: Your machine has drop feed for free-motion sewing, so if you have disengaged feed teeth, you need to re-engage feed teeth for normal sewing. To do this, first move the drop feed lever back to regular sewing position - you won’t see the feed teeth raise up until you then turn the hand wheel toward you one full revolution).

Thread Is Shredding

As you sew, thread can begin to shred for various reasons.

Thread can shred if the needle is dull or damaged, or if the needle is the wrong style and size for the thread being used. The thread should pass freely through the eye of the needle to sew properly. Your manual provides information about needle sizes to be used for the most common types of threads and fabrics.

Some specialty threads, such as metallic threads, will feed more smoothly into the machine if they unreel vertically rather than horizontally, as vertical feed reduces the amount of ‘twist’ on the thread. Your manual shows how to install your vertical spool pin, which your manual calls an Auxiliary Spool Pin.

Needles Are Breaking

Needles can break if they are bent, dull or damaged. Discard  the old needle and insert a new needle, appropriate for the thickness and type of fabric being sewn.

the old needle and insert a new needle, appropriate for the thickness and type of fabric being sewn.

Needles can break if they are not the right size for the fabric thickness you are sewing. Your manual has a chart that offers recommendations for needle size and type, according to the fabric and thread you are sewing.

Needles can break if they have not been correctly inserted into the machine, which can occur if the needle clamp screw was not unscrewed enough when inserting a new needle allowing the needle to be seated all the way up as far as it will go in the needle clamp. Your machine manual has diagrams that illustrate this.

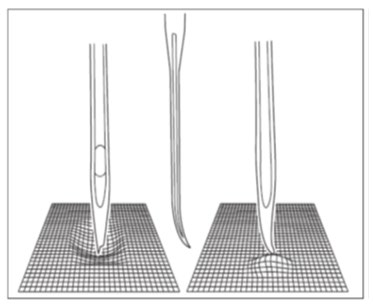

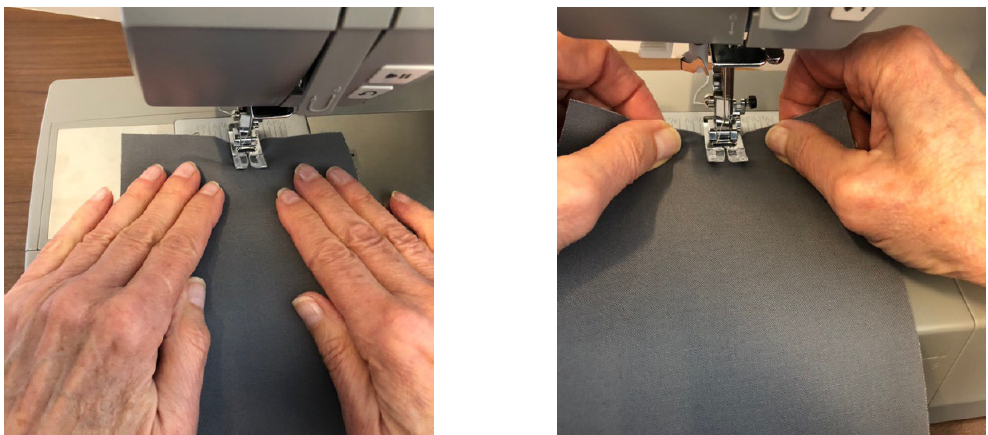

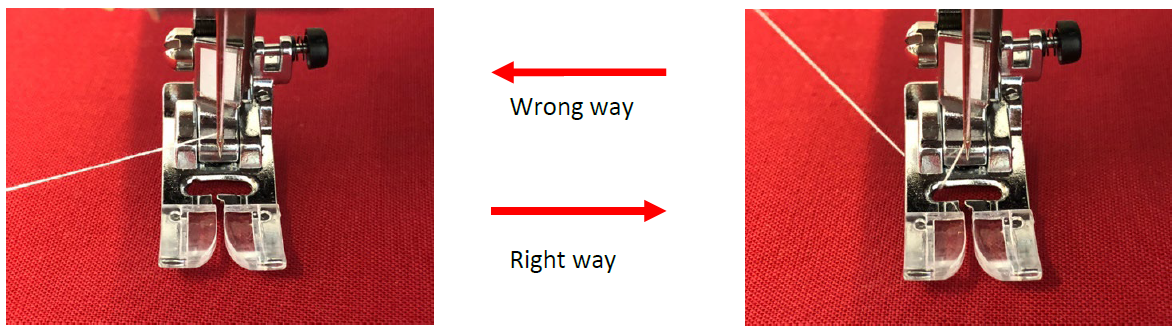

Needles can also break if you are “pushing” or “pulling” the fabric while sewing (see images below), as this can cause the needle to deflect and then break. The feed teeth (or feed dogs) are designed to do the work of drawing the fabric under the foot as you sew – you just need to guide the fabric!

Upper Thread Is Breaking

If the upper thread is breaking, it is possible that the thread path is being obstructed, the machine is not correctly threaded, or the upper thread tension is set to tightly.

Be sure that the thread spool is placed correctly on the spool pin and there are no obstructions (for example, thread getting caught behind the spool cap, behind the spool, or a “rough spot” on the spool itself).

Check also that the thread is unreeling smoothly from the thread spool.

Stitches Are Skipping

If your stitches are skipping on the fabric as you sew, this could be an indication that the needle was inserted incorrectly. Make sure that the needle goes all the way up into the needle clamp and that the flat side (at the top section of the needle) is facing toward the back.

was inserted incorrectly. Make sure that the needle goes all the way up into the needle clamp and that the flat side (at the top section of the needle) is facing toward the back.

Skipping stitches may also occur when the needle is the wrong style for the fabric. For instance, if you are sewing a stretch knit fabric using a regular point needle, you could be experiencing skipped stitches. Switching to a ball point needle will prevent stitches from skipping on stretch knit fabrics.

Worn out or damaged needles can also cause skipped stitches on a variety of fabric types. Discard the old needle and insert a new one, appropriate for the fabric you will be sewing.

Thread is Bunching at the Beginning of Sewing

Threads can get bunched up at the beginning of sewing if the top and bobbin threads have not been properly placed underneath the presser foot before starting to sew. Ensure that both threads are under the presser foot and placed toward the back of the machine before lowering the presser foot to start sewing.

Threads can also start bunching at the beginning of sewing if the stitch length setting is too short for the stitch you have selected. Increase the stitch length setting. You may want to test on a scrap fabric first.

Another reason threads can bunch up is if the wrong presser foot is being used for the selected stitch. For example, satin stitches are very dense, and stitches need to have room under the presser foot to pass freely underneath. If you are sewing a dense stitch pattern, use a Satin Stitch Foot or Open Toe Foot for best results.

Another reason threads can bunch up is if the wrong presser foot is being used for the selected stitch. For example, satin stitches are very dense, and stitches need to have room under the presser foot to pass freely underneath. If you are sewing a dense stitch pattern, use a Satin Stitch Foot or Open Toe Foot for best results.

Stitches Appear to Be Distorted

Stitches can appear distorted on the fabric if you are “pushing” or “pulling” the fabric as you sew. Just let the feed dogs (or feed teeth) do the job of drawing the fabric along under the foot.

Another reason stitches could appear distorted is if the incorrect presser foot is used. For example, dense stitches usually require the use of either a Satin Foot or Open Toe Foot, so that the stitching can pass freely underneath. If the regular All-Purpose Foot is used for dense stitching, stitches could get “stuck” under the foot. Just switch to a presser foot more appropriate for these types of stitches.

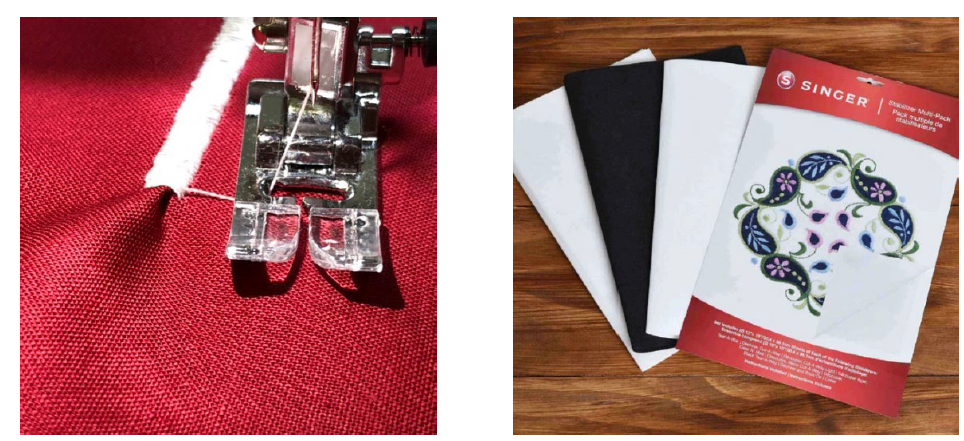

Fabric Is “Tunneling” or “Puckering” under the Stitches

If fabric appears to be pulling together under the stitches, this is a usually a sign that you should use a stabilizer or interfacing underneath the fabric. The stabilizer will support the fabric and stitches when you sew particularly dense stitches, such as when sewing decorative stitches or doing machine applique. More information about the various types of stabilizers available today, including which one to use for the fabric you are sewing, can be found at singer.com. Generally, use a tear-away stabilizer for woven fabrics and a cut-away stabilizer for stretch fabrics.

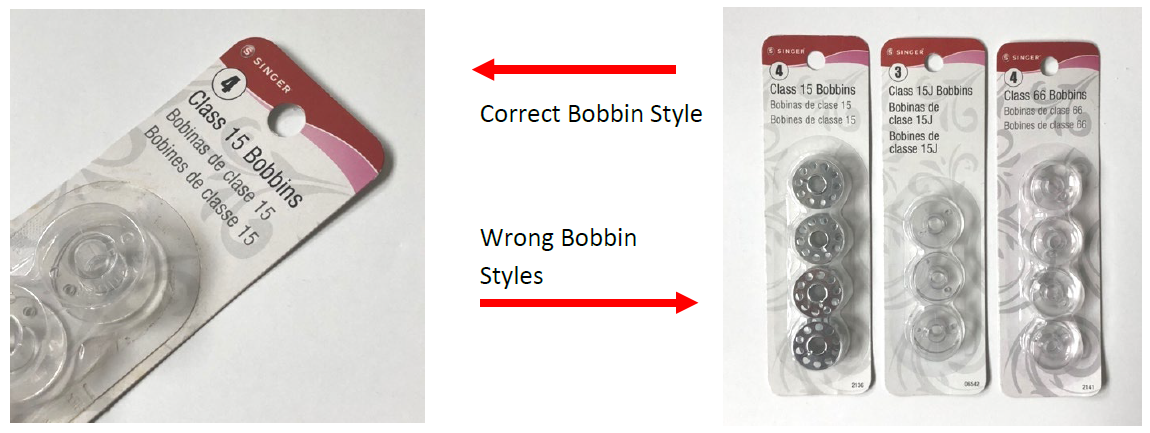

Bobbin Doesn’t Seem to Fit in the Machine

It is important that the bobbin used in the machine is the correct size and style. The machine’s bobbin holder (where the bobbin sits in the machine) is designed to be used with a SINGER® Class 15 transparent bobbin. Because this bobbin is transparent, it’s easy to monitor your thread supply when sewing. When purchasing additional bobbins, be sure to look for Class 15 transparent bobbins. Do not use Class 66, Class 15J bobbins or Class 15 metal bobbins.

Bobbin is Not Working Properly

The bobbin may not work properly if it has been wound with thread that is not appropriate for use with a home (domestic) sewing machine.

When winding the bobbin, do so at a medium speed. Winding bobbins at high speed can cause some types of threads to stretch during the winding process, possibly resulting in skipped stitches.

Take care not to wind the bobbin too full. It should not exceed the bobbin size otherwise the bobbin won’t fit in the bobbin holder.

Threads Are Jamming

Thread choice depends on the type of fabric and the project being sewn. Threads can get jammed due to using types of thread that are not suitable to be used in a home (domestic) sewing machine. Using threads that are too thick or that have coating are likely to cause damage to a home sewing machine and should only be used on industrial sewing machines.

Examples of thread types and weights that are acceptable to use on a SINGER® Heavy Duty machine are: 100% polyester, all-purpose, 100% cotton, machine quilting, 30wt cotton, 12wt cotton, topstitching, jeans topstitching thread, bonded nylon (no larger than #69/Tex 70), and bonded polyester (no larger than #69/Tex 70).

Note: It may be necessary to use an all-purpose thread or 100% polyester thread in the bobbin when using some types of heavier threads in the needle. Threads that are too thick or heavy for the bobbin will cause the bobbin not to feed thread properly.

Examples of thread types/weights that are not recommended for use on a SINGER® Heavy Duty machine are: Threads larger than size #69 (Tex 70), waxed or coated thread of any type, and hand quilting thread.

Be sure to use a needle size that is large enough for the thread being used to make sure that the thread passes freely through the needle’s eye.

If using larger cone-style threads, it is recommended to use an external thread stand.

SINGER and the Cameo “S” Design are exclusive trademarks of Singer Sourcing Limited LLC or its Affiliates. © 2024 Singer Sourcing Limited LLC or its Affiliates. All rights reserved.